From electro-mechanical assembly to precision machining, we offer a full range of manufacturing capabilities to meet your project requirements.

Our comprehensive capabilities span the entire manufacturing spectrum, from design and engineering to final assembly and automation.

Advanced CNC machining capabilities including vertical machining centers and turning centers with 4th axis capabilities for complex parts and components.

Custom automated equipment design and build services for manufacturing processes, including robotic integration and control systems.

2 Vertical Machining Centers, 40" x 20", 4th Axis capabilities for complex machining operations and precision parts manufacturing.

2 CNC Turning Centers for precision cylindrical parts, shafts, and components with advanced control systems and tooling capabilities.

Fiber Laser, 5' x 10' cutting capacity for precision sheet metal cutting, complex shapes, and high-speed production requirements.

Tube Cutting Laser, 8 inch MAX Diameter x 24 feet Long for precision tube cutting, notching, and complex tube modifications.

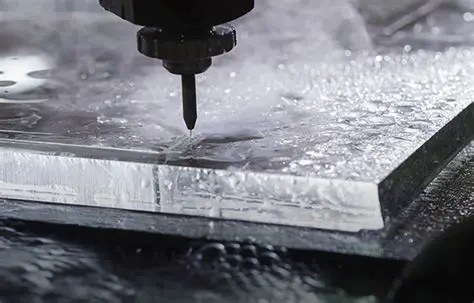

Waterjet, 5' x 10' for cutting a wide range of materials including metals, plastics, composites, and other materials without heat distortion.

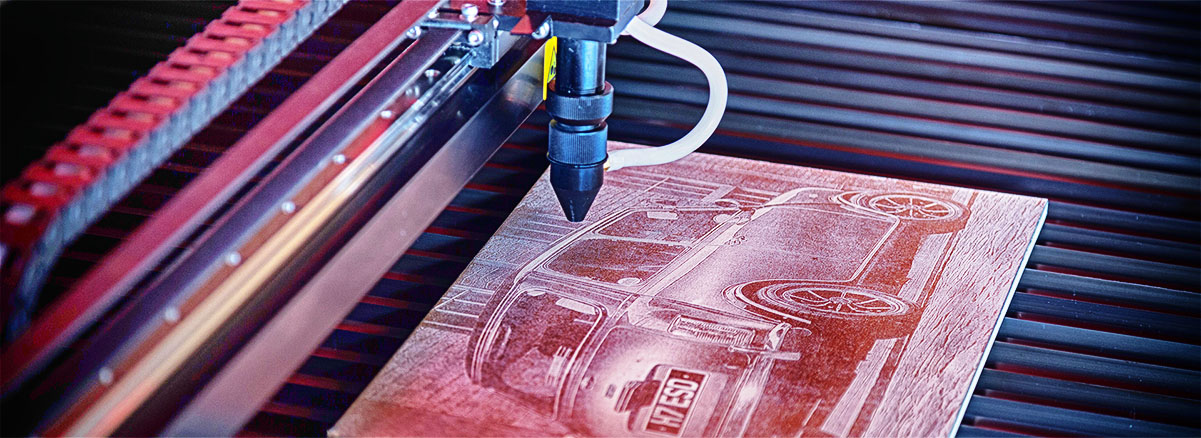

CO2 Engraving Laser 5' x 10' for precision engraving, marking, and cutting of various materials with high detail and accuracy.

Comprehensive welding capabilities including Laser, TIG, and MIG welding for various materials and applications, ensuring strong and precise welds.

CNC Router 5' x 10' for wood and composite panels, plus CNC Press Brake with Wila Tooling for precision sheet metal forming and bending operations.